Technology

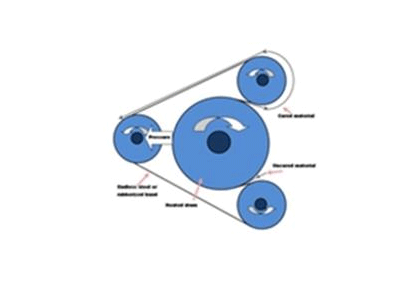

3-roll or 4-roll calendering

- Blah, blah, blah

- Blah, blah, blah

- Etc., etc., etc.

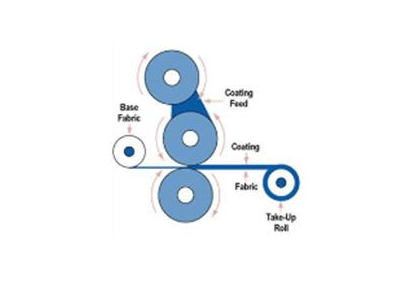

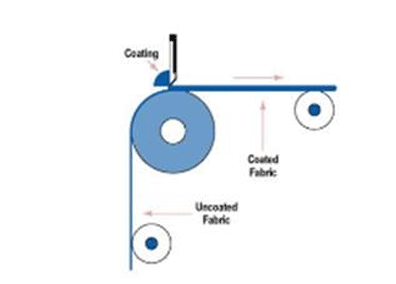

Spread coting

- Blah, blah, blah

- Blah, blah, blah

- Etc., etc., etc.

Spread coating

- Blah, blah, blah

- Blah, blah, blah

- Etc., etc., etc.

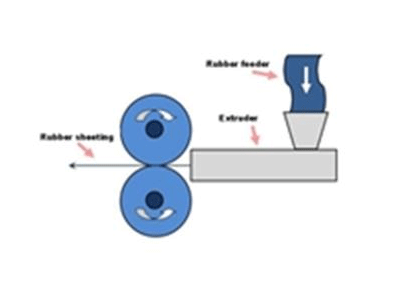

Roller head calendering

- Blah, blah, blah

- Blah, blah, blah

- Etc., etc., etc.

Screen coating

Screen coating

The fabric is passed between rotating screens where

Screen coating

Screen coating

The fabric is passed between rotating screens where

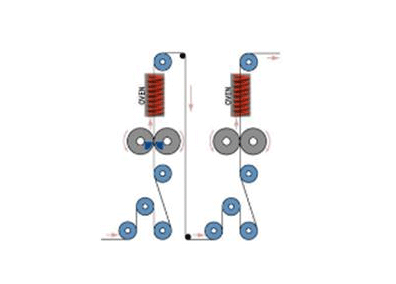

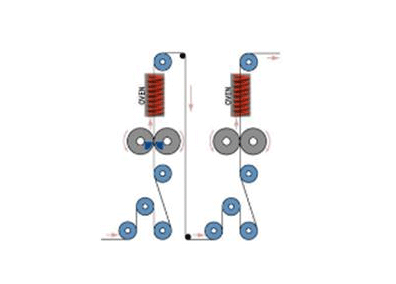

Rotocure

The netting is created between the polymer chains to obtain the final desired properties of the product.

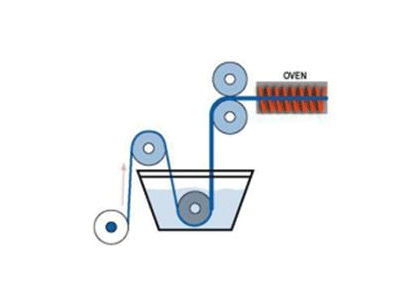

Saturation

The fabric is submerged in a dip tank then passed between pad rollers to control the amount of coating.

Saturation

The fabric is submerged in a dip tank then passed between pad rollers to control the amount of coating.